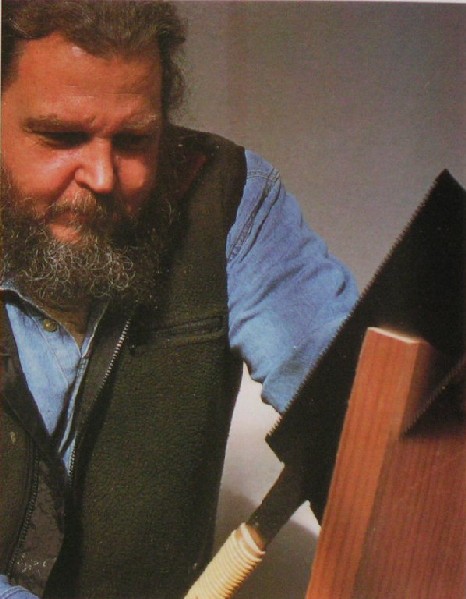

"Metate", by Jay Van Arsdale and Mark Grable

The best thing about a Japanese handsaw (nokogiri) is that it makes it fun to saw. Once you get

the hang of the pull stroke and get the groove going, a sharp and well-conditioned ryoba (a handsaw with crosscutting

teeth on one side and ripping teeth on the other) soon becomes indispensable for all kinds of tasks. The origins

of nokogiri can be traced to an earlier time in China, where bowsaws and a stiff-bladed saw, “the leaf saw” were

found. But it was later, starting in the 1300’s in Japan, that what had been smoldering found its critical flashpoint

and a new life was breathed into already good ideas. There were, to begin with, geologic and climatic forces at

work: the trees, stones, and iron deposits of the country are unique. The real key, though, was Zen and the symbiosis

of Shinto, Confucianism, and Taoism. This culture was the pressure vessel that cooked up the tools, techniques,

and standards. Tradesmen, artisans, and artists formed a distinct class apart from merchants or farmers, and the

founding of the craft trades out of individual craftsmen and their families was integral to maximizing the resources,

both natural and human. The innovations and technical refinement that have occurred since then are the work of

these countless generations of craftsmen, who have dedicated themselves and their resources to achieving a level

of excellence of the highest quality. When Americans started buying handsaws from Japan, there were high expectations,

prompted by spectacular photographs of Japanese shrines, temples, and castles that had been built with these tools.

But few of us in America have realized the potential that we sense in these saws, and the results we get are often

not what we had expected. “This saw doesn't cut right—it needs help” translates into “This saw needs metate.” The

man who does the work is also called a metate. His specialty is nokogiri tune-ups. There are two services all saws

periodically require. The most obvious is re-sharpening the teeth worn by use. The other aspect needed along with

sharpness of teeth calls for proper shape and alignment of the teeth. The metate also removes the distortions,

so that the blade is straight and flat. He files new cutting edges, and sets the teeth. The control of these aspects,

properties distinct to each individual saw, is the metate’s contribution to woodworking’s craft. Without them,

all those thousands of shrines and millions of houses would have been real slow going, if not impossible. For example,

the two guardian figures at the gate of the Great Eastern Temple were erected by a dozen men in just 69 days. They

were not wasting time with dull tools that wouldn’t hold a line. Probably one person in the crew could freshen

a saw and set teeth, or even cut new teeth, but it isn’t likely any could flatten and straighten a saw—they had

enough to master just to build houses!

Nokogiri can be divided into three grades. The best saws have hard steel bodies with soft steel handles welded

on. These are the saws used to make the Great Eastern Temple, Himeji Castle, and thousands of shrines and temples

dating from the 13th Century. Some of these saws are made from tamahagane, a very valuable handmade steel; they

are not meant for beginners, but for artisans with a developed sense of feel. Middle-grade saws are made of one

piece of steel and are softer. The neck is thicker than the body, and the body may also be thinner at the center.

Shindo makes the best of the middle-grade saws. Lower-grade saws are one piece, not hardened, and uniform in thickness.

These are made by machine, and even “finish filing” is done by machine. Some of these saws are good for training,

and for beginning metate. My first saw, a 270mm ryoba from Garrett Wade, cost $50 in 1980, and holds an edge as

well as any Stanley. However, many of these inexpensive saws are not worth sharpening: the steel used in the blade

is made from a manufactured sheet and is soft and lacks the internal steel architecture of the higher quality (and

more expensive) blades. An apprentice-grade nokogiri should last for about 12 hours of sawing before it is no longer

fresh-provided it was set up for the types of wood being cut. (By contrast, the highest-quality nokogiri will cut

40 hours in the same wood before they are no longer fresh.) When a saw loses its edge, it begins to follow the

path of least resistance, which means lack of control. At this point, it no longer guides itself straight in the

cut, and it wanders off line. If you try to push the saw back into line, you are at best wasting your time, and

at worst risking a cracked blade. In fact, a dull nokogiri, even though it is hidden in a grove, is doing the same

thing a dull plane does. When a plane is dull, you can force it into the wood, setting the plane for a deeper cut,

exposing more blade, without the risk of damage to the tool, because it is supported by itself, and penetration

is limited by the mouth of the plane.

This is not the case with nokogiri; in fact, it is just the opposite—the small acute point is hanging out on a thin, hardened, long tooth, which has been bent over slightly by a hammer. One tooth alone is unsupported and unguided. The duller the teeth, the more support and guidance is needed. A sharp saw needs to have about twenty teeth in the wood and the more acute the geometry, the harder and drier the wood, the more teeth are needed. And where there are multiple cutters lined up in a row, the problem of harmonic amplification (and distortion) becomes a factor. In a disposable blade saw, this condition feels like the saw is bouncing and hopping instead of cutting. If you get this all the time, you need another disposable blade. With a sharp, hard-bodied Shindo or Miyano nokogiri, the stiffer body signals you before this actually happens, and is a warning sign you should heed immediately. It means you are about to pull some teeth, knock off a chunk, or bend your sawback out of line. If you get this from a sharp saw, stop and look over what you’re doing. You might need to point up your teeth (something any woodworker can do, and analogous to sharpening a plane or chisel blade), or, if you have done this several times already, you should visit or send your saw to a metate. If your sawing is not fun and satisfying—meaning not accurate, not smooth, and the saw bounces or wanders off the line—then there is probably something wrong with your saw.

A sharp nokogiri should be started into the cut precisely and used with little hand pressure being applied. Use your off-hand thumb as a guide against the layout line, and position yourself to the workpiece with your eyes on either side of the cutline and the socket joint of your saw arm centered on the line. Keep one eye on the near end of the layout line as you pull the saw along right over the line. In this way, you create in your mind’s eye a two-dimensional plane which extends 2-3 feet in all directions from the layout lines, and the saw is congruent with the plane. As you move it back and forth, keeping it in this plane, its teeth will open a clear path for the body of the blade. Some dozuki can split a line made with a knife, producing a cut surface requiring no further adjustment. With these nokogiri, efficiency and elegance become indistinguishable. If you can use this dozuki, you really have developed a true feel and appreciation of wood. Such nokogiri have no set, and so must be flat and straight. Their blades are very thin and can warp from realignment or excessive pressure being applied in the kerf. Because the blades are very thin and the teeth are extremely small, such extra hand pressure only amplifies the force on the teeth. They can jam into the wood pores themselves and possibly twist or break-off. All Japanese saws are raked so that each following tooth along the cutting edge is automatically lower and engaging with the wood as the saw is pulled. This design feature helps reduce the need (and tendency) to put pressure on the saw to help it cut. The saw is only going to cut so fast, and that is determined primarily by the size and shape of the teeth. Large teeth generally cut faster but leave a rougher cut on the surface. But this again is an area where better metate pays off. Proper flattening and tensioning of the blade can be done so that less set (a smaller kerf cut) or no set can be used. On wetter woods, more set is required because of the swelling action of the moisture in the wood cells. Kiln-dried and cured wood responds in a much more stable and precise manner. There are saw sharpeners and saw makers. A saw maker forges the steel into a thin blade, usually in a stack of 3-5 at a time.

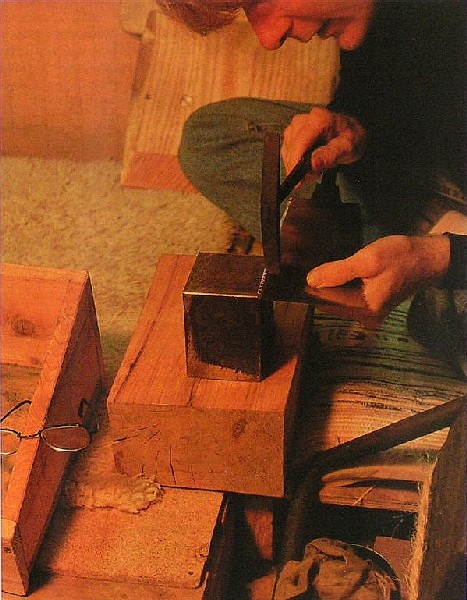

Once the appropriate thickness and shape have been made by hammering, it is sheared and rough-ground into a blade

blank. These blanks are then annealed to relieve internal stress and tempered to give them appropriate hardness

and flexibility. At this point the blank is scraped with a tool called a sen to refine the thickness and surface.

Sen are about 18" long, with pine-with-bark handles on each end, and a forge-laminated steel cutting edge—about

4" long and slightly curved—in the center. The sen is sharpened with a 32-grit stone to create minute serrations

on its cutting edge. The nokogiri blank is clamped on a sen board, making sure that no dust or particles are between

the blank and the board. Holding the sen at about 40°-45° to the nokogiri, 0.001" shavings are removed

from the blank. The verb form of sen means “to plow,” and the tool is actually making “micro-furroughs” on the

surface. But care must be taken not to introduce any permanent waves into the blank, and both sides of the nokogiri

are worked, maintaining the same angle, so that opposite sides have the “furroughs” going in opposite directions.

The blank is flexed to check its thickness, and when it flexes to the right shape—and it’s different for various

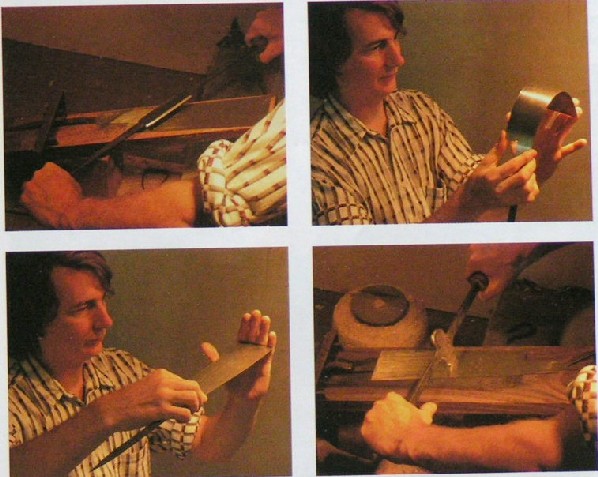

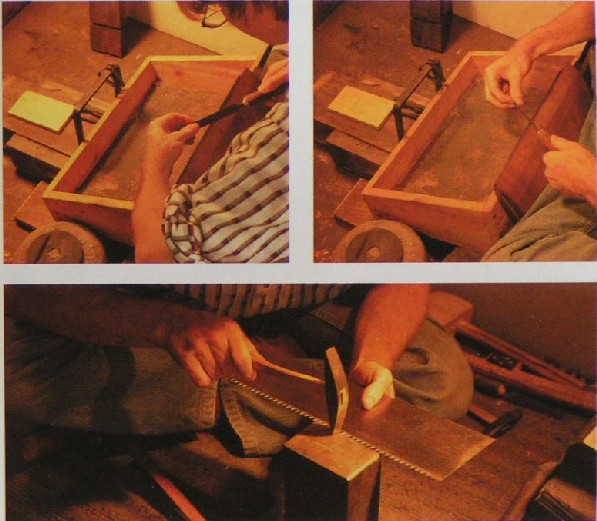

kinds of nokogiri—then it’s the proper thickness. After sen comes miyagi (burnishing). This requires two hours

of rapid, high-pressure arm/elbow grease. The result is a surface that resists rust and has less drag. This last

step in preparing the blank evens the surface and smoothes out any snags. Then comes hizumi (removing “distortion”—the

same word is used, in reference to the human body, for spine and back stretches). The blank becomes a blade once

it is flattened and tensioned.. This flattening and tensioning gives the blade the ability to maintain its shape

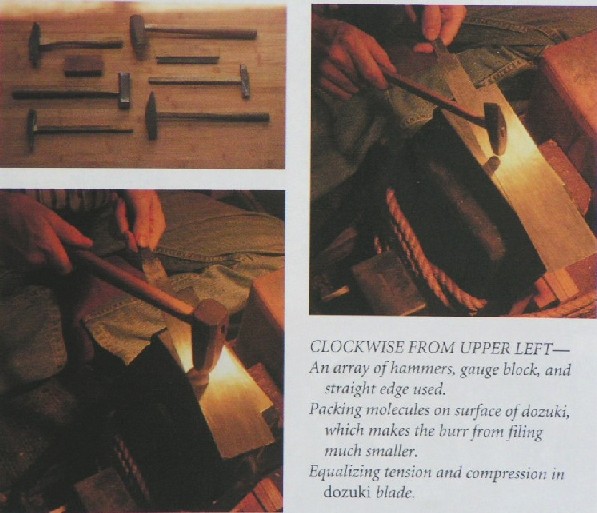

while in tension cutting wood-which is what you want. The tools needed for this include a set of five hammers with

a variety of faces polished and shaped for specific effects, a 300 lb. anvil with a formed, hardened, and polished

face, a wooden anvil (Japanese red oak), and a space with the light oriented to the anvil face and the eye of the

metate. After annealing, the blade is anything but flat. Machines would fracture, or have little effect on such

hard steel. If you have to use a machine, you have to anneal (soften) the steel more, or use softer steel right

off. Using the hardest possible steel, however, allows for a subtle balance of stiffness and flexibility, of thinness

and strength, and of acute cutting geometry and lasting cutting edges. Only over generations could this material

be pushed this close to its limit.

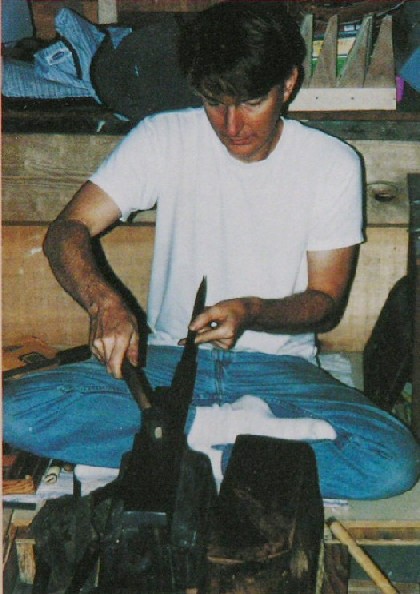

Learning this process of removing curves, twist, valleys, hills, dents, bends, kinks, and other distortions requires

a long time watching someone at work who really knows how to do it; one person could not in one lifetime figure

it out. When you look down the flat side of the blade prepared in this manner, you will see a complex surface composed

of the two processes that produced it. Being a true wrought surface, it will have the appearance of pebbles in

a gentle stream. This is in contrast to blades that are thicknessed by mechanical grinding—a surface with fine

even grinding lines from the handle to the tail. This doesn’t necessarily mean the saw is no good—just that it

wasn’t constructed with the utmost skill. If you forged, packed, hammered, scraped with a sen, hand-burnished a

blade, would you grind it afterwards? If you can’t detect this pebble-like surface, another clear indication of

high quality is whether the tang that the handle fits on is welded on or is the blade one piece of steel. Each

time the blade is flipped over during the sen process, the handle is bent off-center so that it flexes some pressure

onto the sen board. Otherwise, the blank might move enough to let bits of metal shavings underneath, which would

telegraph through as the sen created a dimple under the pressure of the cut. Bending the handle back and forth

off-center requires a low carbon steel, hence the required weld. The welded tang will show the line of two different

metals—hand-forged blade and softer tang material—and a temper coloration, usually blue, at this area. The third

indicator to look for is nuuke, or “puka-puka.” This is a concept that comes from bending the blade to see if all

the tension and flatness have been neutralized. The blade should be held between the thumb and finger on the tail

end and the tang with the other hand. While gently flexing the blade up and down, notice the light reflections

that roll along the surface: they should follow each other in a regular and even pattern. “Puka-puka” results from

an area that is not flat but slightly-cupped—this area will distort the reflected light of the blade in an uneven

pattern. In extreme cases, usually occurring prior to the tensioning phase, the “puka-puka” sound can even be heard

and felt as the blade is flexed. This stretching would be a major drawback to a thin blade moving through a thin

kerf in the wood. Removing this type of distortion is very difficult and tricky work and must be resolved by a

professional—working on it with untrained eyes and hands will result in your blade becoming warped like a potato

chip. On disposable blades, look for tension bands that are roller-pressed onto the surface. The final stage of

the saw-making process is cutting the teeth. Traditionally, this is done by hand with a “feather file” of appropriate

size. On larger-tooth saws and rip teeth a shear maybe used. There are two basic types of teeth used in Japanese

saws. The oldest type of tooth design is the “chisel tooth”—the top cutting edge of the tooth is perpendicular

to the direction of the cut and hence shaped somewhat like a chisel. The other type of tooth is the “knife tooth”

or the edo-me (crosscut) tooth. Its top is sharpened to cut parallel to the pull of the saw, severing the wood

fibers on the outside of the kerf line.

Saws come in many shapes and sizes in Japan, and in addition to rip teeth and crosscut teeth, there are also teeth

especially for crosscutting at an angle, for cutting kiri wood, for cutting branches off living trees, and for

cutting bamboo. The height and width of the tooth’s triangle shape can be adjusted for the characteristics of different

structures in wood. Hardwoods generally have shorter teeth, a bigger base, and are more sturdy. Softwoods are usually

longer in profile and more pointed. A saw set up for cutting soft wood should not be used to cut hardwoods, such

as American oak, because the ring-porous wood structure will grab, twist out of alignment, or even break off the

teeth. An innovation not seen often in traditional Japanese saws, but very useful for Western users, is the “raker

tooth.” These are used along the line of edo-me teeth, usually spaced one every nine teeth. These teeth knock down

the tip of the triangle left from the two knife cuts made on the outer edges of the kerf by the crosscut teeth.

By removing this ridge in the center of the kerf, the outward pressure on the teeth is relieved as the saw is pressed

harder into the kerf by the user and by some of the more porous woods, such as oak. One tooth hanging up isn’t

a problem, but any situation which creates vibrations will cause the saw to look for and find the path of least

resistance. The raker teeth interrupt any vibrations before they are harmonically amplified. In most lesser-quality

blades, the inherent lack of control and precision is compensated for by putting excess “set” in the teeth—bending

the teeth out of line with the blade at the tips—giving a larger and sloppier kerf for the blade to travel in.

This results in a more uneven surface, caused by the tips of the teeth cutting and not the sides of the teeth.

By contrast, a finer blade can have little or no set, but requires more skill and understanding to properly use

it. This simple sketch of the traditional saw-maker’s complex blacksmithing represents the craft at its peak. Rarely

is it seen in the saws available to us today. Metate were held in high regard up until the advent of modern materials

in Japan 30-40 years ago. Traditionally, the people who sell nokogiri also sharpen them, and they do the final

sharpening before the final sale. This is in contrast to the standardization of mass production, and the high volume

(and economic expectations) which usually prohibit experimentation and custom work.

Today, most teeth are machine-cut, and sharpening and setting of the teeth and tensioning are processes that machine

production have mostly taken over as well. Once the maker’s hands have been removed from these significant parts

of the process, it’s only logical to use other steels and processes that are more adaptable to the new methodologies.

It is not possible to machine-manufacture disposable blades with hard bodies, because tempering creates distortions

which machines cannot remove. Disposable blades are soft enough a machine can do all the work, and the connection

to the handle is minimal, so it’s difficult to learn to saw with such mushy feedback. You can’t do much more than

cut dovetails, which are shallow, before you have to start cleaning up everything with chisels. In the United States,

many saws have been sold that don’t work from day one. Such different standards are bound to generate disappointment

and confusion. The stamp of progress has substituted its own methodology and criteria on the process. What it has

given in return is a selection of saws with a wider range of perfection, quality, and price. Once the recipients

of the saw-maker’s work had a familiar face; now, like most modern businesses, he and the middlemen are looking

for customers beyond the neighborhood. So, it seems, world marketplace forces will again establish a new level

of production to satisfy a more diverse clientele. What will the next generation of craftspeople have access to,

know about, use, and buy? Hopefully not tools as products of the cheapest economic bottom line. When this knowledge

is forgotten, it will not be coming back anytime soon. Not only will we lose one of the roots basic to this tradition,

but we will be left with fewer choices as we face the challenge of developing our discipline and skills in a disposable

future. This craft is a highly evolved complex of understanding and skill, a union of tool-making and tool use.

The more accurate, consistent, and mutually reinforcing all this is, the more efficient, useful, and long-lived

the tool can be. To me, the greatest value of all this lies somewhere else. It is in the space I reach for in my

work. A place where I can trust my tools to be my teachers and for my work to reflect my intentions.

Jay Van Arsdale lives in Oakland, California; Mark Grable is in Springfield, Vermont, and can be reached at japanesehandsawsharpener@yahoo.com